10 REM Pi_bi_step

20 REM Control a bi-polar stepping motor wit the Raspberry Pi

30 REM Jochen Lueg

40 REM http://roevalley.com (bottom of the page)

50 REM Limavady, January 2013

60 REM Version 1.0

70

80 ON ERROR PROCerror

90 PROCinit

100 OFF

110 OSCLI"RMEnsure GPIO 0.00 RMLoad GPIO"

120 OSCLI"RMensure GPIO 0.40 ERROR Please install the GPIO module"

130 PROCsetupGPIO

140

150

160 PRINT

170 PRINT " Motor controls"

180 PRINT

190 PRINT " Left . . . . . . Z"

200 PRINT " Right . . . . . . C"

210 PRINT " Stop . . . . . . X"

211 PRINT

220 PRINT " Full step . . . . . . F"

230 PRINT " Half step . . . . . . H"

240 PRINT

250 PRINT " Fastest . . . . . . 1"

260 PRINT " to"

270 PRINT " Slowest . . . . . . 9"

280 PRINT

290 PRINT " Press 'Q' to leave the program"

300

310 REPEAT

320 Key$=INKEY$(0) : REPEAT UNTIL INKEY(0)=-1

330 IF Key$="c" OR Key$="C" Direction$="Right"

340 IF Key$="z" OR Key$="Z" Direction$="Left"

350 IF Key$="q" OR Key$="Q" Direction$="Finished"

360 IF Key$="x" OR Key$="X" Direction$="Stop"

370 IF Key$="h" OR Key$="H" Mode$="Half"

380 IF Key$="f" OR Key$="F" Mode$="Full"

390 IF Key$="1" T%=150*S% :Speed$="Fast"

400 IF Key$="2" T%=200*S% :Speed$="Fast-1"

410 IF Key$="3" T%=300*S% :Speed$="Fast-2"

420 IF Key$="4" T%=625*S% :Speed$="Fast-3"

430 IF Key$="5" T%=1250*S% :Speed$="Half"

440 IF Key$="6" T%=2500*S% :Speed$="Slow+3"

450 IF Key$="7" T%=5000*S% :Speed$="Slow+2"

460 IF Key$="8" T%=10000*S% :Speed$="Slow+1"

470 IF Key$="9" T%=20000*S% :Speed$="Slow"

480 IF Direction$="Right" AND Mode$="Full" THEN PROCfull_step_right

490 IF Direction$="Right" AND Mode$="Half" THEN PROChalf_step_right

500 IF Direction$="Left" AND Mode$="Full" THEN PROCfull_step_left

510 IF Direction$="Left" AND Mode$="Half" THEN PROChalf_step_left

520 IF Direction$="Stop" PRINTTAB(1,19)"Motor

stopped

"

530 IF Direction$="Stop" PROCall_off: Direction$="Wait"

540 IF Direction$ <> "Wait"

PRINTTAB(1,19);Mode$;" step. Turning ";Direction$;" with speed

";Speed$;" "

550 UNTIL Direction$="Finished"

560 PROCclose

570 QUIT

580

590 DEFPROCall_off

600 FOR J%=1 TO 4

610 SYS"GPIO_WriteData",Port%(J%),0

620 NEXT

630 ENDPROC

640

650

660 DEFPROCfull_step_right

670 FOR J%=4 TO 1 STEP-1

680 SYS"GPIO_WriteData",Port%(J%),1

690 SYS"GPIO_WriteData",Port%(J%-1),0: FOR I%=1TO T%:NEXT

700 NEXT

710 ENDPROC

720

730

740 DEFPROCfull_step_left

750 FOR J%=1 TO 4

760 SYS"GPIO_WriteData",Port%(J%),1

770 SYS"GPIO_WriteData",Port%(J%-1),0: FOR I%=1TO T%:NEXT

780 NEXT

800 ENDPROC

810

820

830 DEFPROChalf_step_right

840 FOR J%=4 TO 1 STEP-1

850 SYS"GPIO_WriteData",Port%(J%),1

860 SYS"GPIO_WriteData",Port%(J%-1),0: FOR I%=1TO T%:NEXT

870 SYS"GPIO_WriteData",Port%(J%+1),1: FOR I%=1TO T%:NEXT

880 NEXT

900 ENDPROC

910

920

930 DEFPROChalf_step_left

940 FOR J%=1 TO 4

950 SYS"GPIO_WriteData",Port%(J%),1

960 SYS"GPIO_WriteData",Port%(J%-1),0: FOR I%=1TO T%:NEXT

970 SYS"GPIO_WriteData",Port%(J%+1),1: FOR I%=1TO T%:NEXT

980 NEXT

1010 ENDPROC

1020

1030

1040 DEFPROCinit

1050 W%=0

1060 Direction$="Stop"

1070 S%=200

1080 T%=S%*150

1090 Speed$="Fast"

1100 Mode$="Full"

1140 ENDPROC

1150

1160

1170 DEFPROCerror

1180 PRINT REPORT$;" at line ";ERL :

1190 FOR J%=1 TO 4

1200 SYS"GPIO_WriteData",Port%(J%),0

1210 NEXT

1230 END

1240 ENDPROC

1250

1251

1260 DEFPROCsetupGPIO

1270 DIM Port%(5) : Port%()=15,24,23,18,15,24

1280 SYS"GPIO_EnableI2C",0

1290 SYS"GPIO_ExpAsGPIO",2

1300 FOR J%=1 TO 4

1310 SYS"GPIO_WriteMode",Port%(J%),1

1320 NEXT

1340 ENDPROC

1350

|

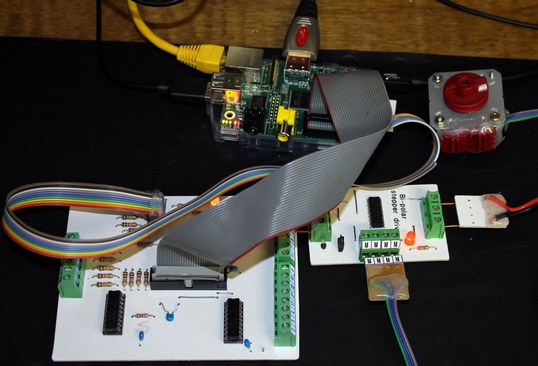

Bi-polar stepping motors use only two coils and are easily recognized

because they only have four wires. Most unipolar steppers can be used in

bipolar mode by ignoring the two centre taps. Because bi-polar stepping

motors produce the rotating magnetic field by reversing the current in

both coils, controlling them is much more complicated than controlling

their unipolar

cousins.

Bi-polar stepping motors use only two coils and are easily recognized

because they only have four wires. Most unipolar steppers can be used in

bipolar mode by ignoring the two centre taps. Because bi-polar stepping

motors produce the rotating magnetic field by reversing the current in

both coils, controlling them is much more complicated than controlling

their unipolar

cousins.